About the "Stirling" and the student ...

Robert Stirling.

In 1843, his son, James Stirling, used his father’s engine in a factory where he worked as an engineer. Well, already in 1938, Stirlings with power up to 200 hp were created. and efficiency equal to 30 percent.

The principle of operation of this engine is to alternate the heating and cooling of the working fluid in a fully closed cylinder. Usually, the working medium is air, but hydrogen, helium, as well as freons, nitrogen dioxide, liquefied propane-butane, and even water can be used. Moreover, it remains liquid throughout the thermodynamic cycle. That is, the design of the engine is extremely simple and uses a well-known property of gases: from heating, their volume increases, and from cooling it decreases.

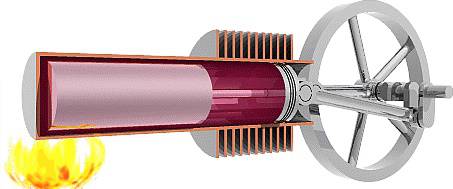

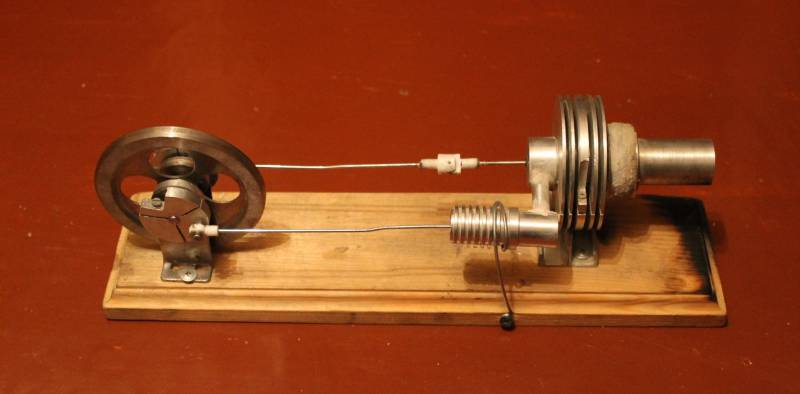

One of the many homemade Stirling.

In the Stirling engine is used ... "Stirling cycle", which in its thermodynamic efficiency is not only worse than the Carnot cycle, but even has some advantages. In any case, it is the "Stirling cycle" that allows you to get a working engine made from an ordinary tin can, in just a couple of hours.

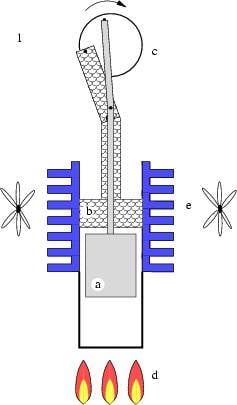

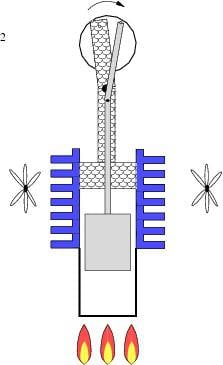

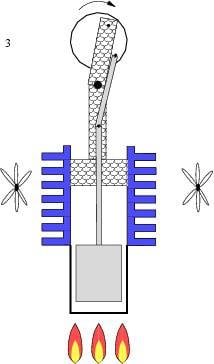

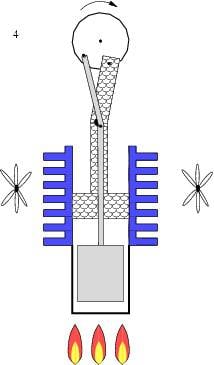

Beta Stirling Device.

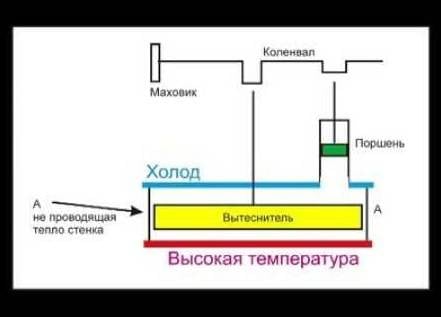

The Stirling cycle itself includes four main phases and two transitional phases: heating, expansion, transition to a cold source, cooling, compression, and a transition to a heat source. Well, we get useful work in the process of expanding the volume of heated gas.

Phase 1.

Phase 2.

Phase 3.

Phase 4.

The working cycle of the Stirling engine beta type: a - displacement piston; b - working piston; c - flywheel; d - fire (heating area); e - cooling fins (cooling area).

It works like this: there are two cylinders and two pistons. An external source of heat - and they can be even burning firewood, even a gas burner, even sunlight - raises the temperature of the gas in the lower part of the heat exchange cylinder. There is a pressure, and it pushes the working piston upwards, and the displacement piston fits loosely against the walls of the cylinder. Further, the flywheel, scrolling, pushes it down.

Stirling scheme from the can.

At the same time hot air from the bottom of the cylinder enters the cooling chamber. In the working chamber, it is cooled and compressed, and then the working piston rushes down. The displacement piston goes up, and thus the cooled air moves to the bottom. The cycle is thus repeated. In Stirling, the movement of the working piston is shifted by 90 ° relative to the propellant piston.

Photo of Stirling from a tin can.

Over time, many “Stirlings” of different designs appeared, spelled out in the Greek alphabet: alpha, beta, gamma, which have differences in the working cycle. The principal differences between them are small and come down to the location of the cylinders and the sizes of the pistons.

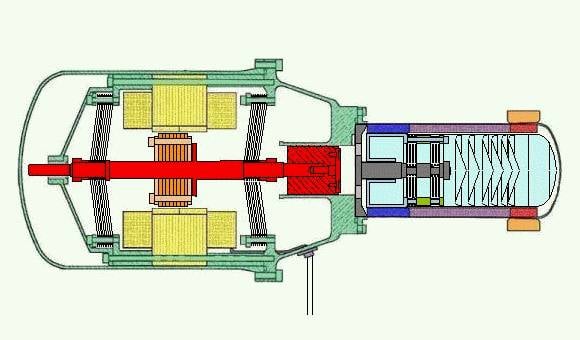

Stirling engine with linear alternator.

Alpha Stirling has two separate power pistons in different cylinders: hot and cold. The hot piston cylinder is in a heat exchanger having a higher temperature, and the cold piston cylinder is, respectively, in a colder one. The regenerator (that is, the heat exchanger) is located between the hot part and the cold part.

Beta Stirling has only one cylinder, hot from one end and cold from the other. Inside the cylinder moves the piston (from which the power is removed) and the displacer, which changes the volume of its hot zone. Gas is pumped into the hot part of the cylinder from the cold part of the cylinder through a regenerator.

Gamma Stirling also has a piston and a displacer, and two cylinders are cold (where the piston moves, from which power is removed) and hot (where the displacer moves accordingly). The regenerator is external, in this case it connects the hot part of the second cylinder with the cold part and at the same time with the first (cold) cylinder. The internal regenerator in this case is a part of the displacer.

There are variations of the Stirling engine that do not fall under these three classical types: for example, a Stirling rotary engine, in which problems of tightness are solved and there is no crank mechanism, since it is rotary.

What are the good Stirling and what they are bad? First of all, they are omnivores and can use any temperature difference, including that between different layers of water in the ocean. Combustion in them is permanent, which results in efficient fuel combustion, which means that it is more environmentally friendly. In addition, he has no exhaust. Less noise - no “explosions” in the cylinders. Less vibration, for example, in beta-stirling. The working body is not consumed by stirling. The design of the engine is extremely simple, it does not require gas distribution mechanisms. The starter is not needed, as well as the gearbox.

The simplicity and the absence of a number of "gentle" nodes provide "Stirling" unprecedented performance for all other engines of tens and hundreds of thousands of hours of regular work.

Swedish submarine "Gotland".

Stirling very economical. Thus, the conversion of solar energy into electricity by means of stirling yields a higher efficiency (up to 31,25%) than heat engines that operate on a couple. To do this, "Stirling" is set at the focus of a parabolic mirror, which "watches" the sun so that its cylinder is constantly heated. It was at such a facility in California that the above-mentioned result was obtained in 2008, and now a large solar station is being built there. You can attach them to the blast furnace shell and then continuous smelting of cast iron will give us a lot of ... cheap energy, because now this heat is wasted!

The disadvantage of the stirling, in general, is one. It can overheat and then it will immediately fail. In addition, to achieve high efficiency in the cylinder must be a gas under very high pressure. Hydrogen or helium. And this is the exceptional accuracy of fitting all its working units and special high-temperature lubricant. Well, the dimensions ... ICE combustion chamber is not needed. Stirling without it can not! And this is an extra volume and insulation and cooling system!

"Litter" - a Japanese submarine with Stirling engines.

However, a change of priorities is likely to make way for Stirling engines. If the focus is on environmental friendliness, then it will be possible to say goodbye to the internal combustion engine once and for all. In addition, they have high hopes for the creation of promising solar power plants. They are already being used as autonomous generators for tourists. And some companies have established production of Stirlings, which operate from a conventional gas oven stove. NASA is also considering options for "stirling-based" power generators driven by nuclear and radioisotope heat sources. In particular, such a stirling, together with an electric generator, is planned to be used in the NASA space expedition to Titan.

"Litter" - the layout.

Interestingly, if you start the Stirling engine in reverse mode, that is, turn the flywheel from another engine, it will work as a refrigerating machine (Stirling reverse cycle), and it was these machines that turned out to be very effective for producing liquefied gases.

Well, now, since the site is military, we note that the Stirlings were tested on Swedish submarines back in the 60 of the last century. And then in 1988, the Stirlings became the main engine of the Nakken-type submarine. With them, she was sailing underwater for more than 10 000 hours. The Nakken-type Gotland-type submarines, which became the first submarines equipped with Stirling engines, allowed them to be under water until the 20 day. Today, all submarines of the Swedish Navy have stirling motors, and Swedish shipbuilders have worked out the original technology for installing such engines on conventional submarines, by plunging an additional compartment with a new propulsion system into them. They work on liquid oxygen, which is then used in the boat for breathing, and it is noted that they have a very low noise level. Well, the above-mentioned disadvantages (dimensions and the problem of cooling) on an underwater warship are not significant. An example of the Swedes seemed to the Japanese people to pay attention to, and now the Stirlings stand on Japanese submarines of the type "Soryu". These engines are considered today as the most promising all-mode single engines for submarines of the 5 generation.

And this is what Stirling student of the Penza State University Nikolai Shevelyov looks like.

Well, now quite a bit about what we have ... "bad youth." I’m coming to 1 September for students - future engine engineers, asking them traditional questions, what they read (practically nothing!), What they like (with this position a little better, but mostly legs, not head!), What technical journals Known are “Young Technician”, “Model Designer”, “Science and Technology”, “Popular Mechanics” ... (none!), and here one student declares to me that he is interested in engines. One of 20, but this is already something! And then he tells me that he made the Stirling engine. I know how to make such an engine out of an ordinary tin can, but it turned out that he did something much more spectacular. I say: “Bring it!” - and he brought it. “Describe how I did it!” - and he described, and I liked his “essay” so much that I bring him here without any changes or abbreviations.

Getting started - "creative chaos."

“I always liked the technique, but especially the engines. With great interest, doing care, repair and customization. When I learned about the Stirling engine, I was fascinated by it, like no other engine. The world of Stirling is so diverse and large that it is simply impossible to describe all possible options for its execution. No other engine will give such a variety in terms of design, and most importantly the opportunity to make it yourself.

There were ideas to make a model of the engine from a tin can and other improvised means, but it is not in my rules to do "how it came and what it got". Therefore, I decided to seriously approach the implementation of this task, to begin to prepare theoretically. He studied the literature on the Internet, but the search did not bring the desired result: review articles and videos, the lack of drawings of models of this engine. Finished models were sold at too high a price. In addition, a great desire to make everything yourself, to understand the principle of action, to debug and conduct tests, to get useful work from this engine and even try to find an application for it in the economy.

“Turning affairs!” (A clever student, he filmed the entire process of work for memory. Present, citizen, film and photo documents confirming ... and here they are!)

I asked around on the forums, and shared with me the literature. This was the book "Stirling Engines" (Authors: G.Rider and C. Hooper). It reflected all story this type of engine building, why the rapid development has stopped, and where these engines are still used. From the book I learned in more detail all the processes occurring in the engine, I found answers to interesting questions. It was interesting to read, but I wanted to practice. Of course, there were no drawings for garage models, as well as on the Internet, well, of course, except for the model from a tin can and foam rubber.

Much to my happiness, the person who was selling the Stirling models laid out a course on making such models, he set it up at that time for 20 $, I wrote to him and paid for the course. After reviewing all the videos, in each of which he explained some particular type of Stirling, I decided to do exactly the high-temperature stirling gamma type. Since he was interested in me with his design, characteristics and appearance. From the video course, I learned the approximate ratio of cylinder diameter, piston diameters, what should be the gaps, roughness, what materials to use in the manufacture, some nuances of construction. But nowhere was the size of the author's engines, only approximately the ratio of the sizes of the nodes.

I myself live in the village, it can be said in the suburbs, my mother is an accountant, and my dad is a joiner, so it was inappropriate to turn to them for advice on building an engine. And I turned to my neighbor, Gennady Valentinovich, for help, he worked at the now-collapsing factory of KZTM in Kuznetsk. For him, this work seemed rather unusual, he listened to me carefully, looked at my sketches, corrected something.

In general, the next day, Gennady Valentinovich brought me an aluminum blank with a length of about 1 m and a diameter of about 50 mm. I was very happy, sawed off the pieces I needed, and the very next day I went to school to try to grind the heater and refrigerator for my internal combustion engine. I sharpened on an educational lathe (on which grandfather Lenin worked).

Of course, there was no accuracy there, the external part of the heater turned out to be quite good, but the cylindrical part itself under the piston was on a cone. Trudovik explained to me that the boring tool goes to bend, because the machine for such things is rather small and weak. The question arose of what to do next ... It was lucky that my mother at that time worked as an accountant at a private enterprise, which was a former Avtomobilzavod. Valery Aleksandrovich (the director of this plant) turned out to be a wonderful person and helped me a lot, I was already provided with a professional Soviet machine and turner who helped me. It went more fun, and literally a week later, almost everything was ready, the assembly of the engine began. There were interesting moments in the construction, for example: the shaft, on which the flywheel was pressed on, was given to the precision mechanics workshop at another plant (in order to get the necessary precision for the bearings); the refrigerator was sharpened on a lathe, and the places for fixings were made by a milling machine, the flywheel was ground on a grinding wheel. For me it was very interesting and exciting. The workers at the factory thought that I was a student, and I was writing some kind of scientific work. I was sitting in the factory until late evening, and they brought me home in Valery Aleksandrovich’s official car. Starting the engine took place in a large environment of the factory workers, it was all very interesting. The launch was a success, but the engine worked poorly.

The result is crowned! The stand angle burned during the test.

The drawbacks were revealed, the plastic hinges were replaced with fluoroplastic, the flywheel was lightened and balanced, the piston received a fluoroplastic attachment for lower heat transfer, and the refrigerator became with a larger cooling area. After fine-tuning the engine has significantly improved its technical performance.

I myself was delighted. Coming to my house, friends first of all approach it to him, they are interested, they ask to run. Gennady Valentinovich drove to show the stirling to his job, everyone was very interested, didn’t even have to call someone, everyone came, looked, were interested. ”

The young man’s name is Nikolai Shevelev, and he is the headman of the group. I took him to the dean, and the three of us spoke very well together. And then I remembered the statistics that to advance humanity along the path of scientific and technological progress, the entire 2% of the population of the planet is enough. I counted the total number of students and realized that ... there is no need to worry. With such as Nikolai, progress will be ensured to us anyway!

Information