From AK-47 to AKM

The adoption of the AK-47, despite a number of shortcomings, was undoubtedly a great achievement of the Russian armory Sciences. The machine was loved by the troops for the simplicity of the device, the reliability and compactness (compared to the SKS carbine). However, it turned out to be not cheap and rearmament placed an exorbitant burden on the country's bloodless economy and threatened to stretch for decades. The production of new machine guns only slightly exceeded their decline as a result of intensive combat training. Therefore, SKS carbines were in service even with motorized rifle units until the mid-60s, and in some military branches, and even more. In addition, increasing requirements for troop mobility made it necessary to reconsider the weight load of the equipment of each soldier, the mass of weapons with ammunition in which was (for the AK-47 with four magazines and 120 rounds of ammunition, a belt, a bayonet, an ammo pouch and a spare part) 9 kg. All these requirements will become valid only in 1953 when developing the tactical and technical requirements for the new lightweight machine. In the meantime, back to 1951

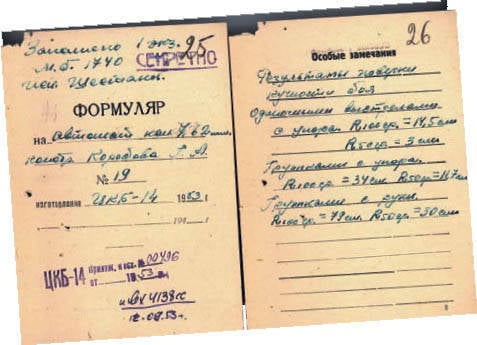

The shortcomings of AK-47, which were not eliminated either before being put into service, or when starting mass production, encouraged a number of other gunsmith designers to continue the design work on the automatons of their designs, and the GAU took a wait-and-wait attitude (and suddenly it turns out), but The Ministry of Defense Industry funded them. The pioneer of these works was the representative of TsKB-14, a talented Tula designer G. A. Korobov. Already in 1951, he presented his own highly original machine design with a rarely used automatics operation scheme - a semi-free gate to the ground tests. In general, the machine was distinguished by simplicity of design and manufacturability of parts (and, therefore, low labor intensity and cost), most of which were made by cold forging from sheet steel. The absence of a rigid locking assembly not only eliminated time-consuming operations to debug it, but also unloaded the receiver, which significantly reduced the weight of the machine (on 0,65 kg). An important economic factor was the use of commercially available store from AK-47 without any additional finishing touches. The principle of operation of the automation was founded:

- unloading of the chamber by grooves of a large cross-section, which ensured early and effective unloading of the chamber;

- on the back of the liner in the chamber during the shot by the free mass of the inertial body, acting on the sleeve not directly, but through a lever, which created the necessary stop of the sleeve by a small mass of the free inertial body.

Before firing, the parts of the shutter are in the extreme forward position, namely:

- a combat larva with a drummer and an ejector rests on the trunk stump;

- the lever is in an almost vertical position, leaning with the lower edge on the stop of the jumper of the receiver in its middle part, with the neck on the combat larva, and with upper feathers it perceives longitudinal pressure forward from the stem of the bolt, supported by a return spring.

When fired, the pressure from the liner is transmitted through the combat larva to the lever, which, relying on the box's support, turns and throws the stem of the bolt back. During the turn of the lever, the pressure in the barrel drops to atmospheric, and the stem of the bolt receives a reserve of kinetic energy sufficient to roll back to the extreme rear position. However, it was not possible to fully evaluate the automatic Korobov for all characteristics due to the low survivability of the barrel coupling. The fact is that the main part of the chamber, with the exception of its rear part, was formed in the barrel. The barrel was mounted with a tensioner in the coupling, which formed the lower walls of the grooves and the rear part of the chamber length 8 mm.

In 1952, modified automata were submitted for testing based on the conclusion of the SPM GAU from 24.08.51.

Automatic Korobov TKB-454 arr. 52 g. With metal butt

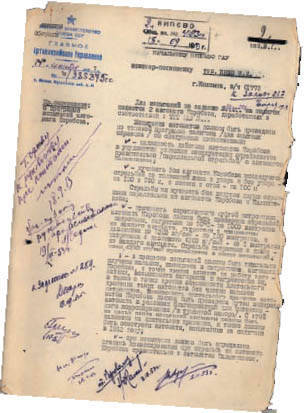

The tests carried out in 1952 showed that according to the reliability of the automation in normal and different operating conditions, the survivability of parts of the Korobov machine satisfies the TTT No. 3131-45, and has advantages over the Kalashnikov machine gun in weight, accuracy of combat for low-trained shooters, simplicity of design, development and production. At the same time, during testing, the low service strength of many parts and a number of design flaws in individual components, the list of which took up two sheets, were revealed.

In 1953, TsKB-14 submitted for testing the modified Korobov automata. With these machines, the chamber with grooves, with the exception of the pool entrance, was formed in the barrel coupling, almost all parts were strengthened, and the cadmium of moving parts (rather expensive and harmful production) was replaced by phosphating.

By this time, tactical and technical requirements for the new TTT machine no. 006256-53 were developed and tests were carried out for their compliance.

The test results showed the feasibility of most of the modifications of automata. However, it was

identified a number of features inherent in the applied scheme of automation:

- the initial bullet velocity is on average 38,5 m / s lower than that of AK-47 due to the presence of grooves in the chamber;

- an uneven rate of fire in both normal and degraded conditions, the change of which reached 185 rds / min. (three times more than AK). The reason is in the specific operation of the self-timer (constructive), which plays the role of counter-rebound of the stem of the shutter and the moderator of the firing rate;

- shooting bursts of regular blank cartridges is impossible. Development of a reinforced blank cartridge is required;

- muzzle flame when firing is much larger in magnitude and intensity than AK (force length 200-250 mm against 30-40 mm), which is explained by the less complete explosive decomposition of gunpowder due to the use of a semi-free gate. The pressure curve in the chamber has a smaller maximum pressure, a longer pressure build-up time to the maximum, a longer pressure time until the bullet leaves.

Despite the obvious shortcomings of the system, two positive points noted - the weight per 465 g is less than AK-47 and the costs in machine-hours are about 2,2 times less than for AK-47 - undoubtedly influenced the final conclusion: “For the final decision on the need for to continue further work on the Korobov machine gun, it is advisable to make a small series (approximately 20 units) of such machine guns and subject them to extensive comparative tests with Kalashnikov guns on the “Shot” courses in the rifle tactical committee, and pytatelnom range and long service life in the army. " What was implemented.

A research work was carried out to investigate the automatics of the Korobov automaton, which substantiated the almost impossibility of creating a reliable sample according to this scheme. But G. A. Korobov never gave up in the face of technical difficulties and continued to work on the system until 1956.

But it will be yet to come. And in 1953, it seemed that the “star” of M. T. Kalashnikov and his AK were already fading.

- Yuri Ponomarev

- http://kalashnikov.ru"rel =" nofollow ">http://kalashnikov.ru

Information